© tetronik GmbH. All rights reserved.

© tetronik GmbH. All rights reserved.

Employee safety at the pharma park

Personal security over an area of 10 hectares

Safety is a top priority at Siegfried Holding AG. Founded in 1873, the company develops and produces chemical agents and substances at its headquarters in Zofingen, Switzerland. Strict regulations apply, ranging from access restrictions and mandatory protective clothing to smoking and cell phone bans.

Siegfried needed a good solution for lone worker protection at its 100,800 m² site in Zofingen, which has more than 600 employees and around 50 buildings. tetronik GmbH was able to tick the most boxes on a long list of requirements with its DAKS solution portfolio.

Brief introduction to the customer

As one of the leading contract development and manufacturing organizations (CDMO), Siegfried Holding AG manufactures both active ingredients for medicines and finished drugs for its global customers. The Siegfried Group generated sales of one billion Swiss francs in 2021 and employs 3,500 people worldwide at a total of 11 locations.

Strict safety regulations must be followed at the headquarters in Zofingen. The site has its own highly trained factory fire department, which conducts regular drills. The Siegfried Group's motto, “expect more,” and Swiss government regulations on occupational safety were decisive factors in the pursuit of improvements in the area of lone worker protection.

Key customer requirements

- Certified lone worker protection in accordance with DGUV (similar to the Swiss EKAS)

- Option of voice communication with the accident victim

- Location of the accident victim if, for example, there is no response or a call for help

- Visualization of the exact location of accident victims for rescuers

- Explosion protection suitability (ATEX) of end devices and personal emergency signal devices

- Reliable radio coverage despite buildings with the effect of Faraday cages

- Option to integrate already purchased devices

- Cost efficiency and economic viability of the solution

Lukas Kocher

Walter Fiechter

A full package, just like when you travel: All-inclusive!"

Lukas Kocher

The challenge

As a chemical production site, the Zofingen location must comply with strict occupational safety regulations. In 2017, initial improvements were made to the existing personal safety system in accordance with EKAS regulations (the Swiss equivalent of the German DGUV), but not everything was working to complete satisfaction.

The biggest problem was that stable voice communication was sometimes not possible and people could not be located. How do you find a single person on a site measuring 420 by 240 meters, not to mention the additional volume of numerous floors in over 50 buildings? And it wasn't just the numerous buildings that caused concern for Mr. Kocher, IT project manager and member of the factory fire department at Siegfried AG, but also the underground, multi-story energy channel: "When everything down there is filled with smoke, it's like nighttime! Just imagine getting lost down there! Finding someone without a location system is simply impossible.

The restrictions imposed by the Ex zone, which applies in almost all areas, presented an additional difficulty. The new devices not only had to offer more and better functionality than the previous dead man's switches, but also had to be suitable for use in explosion protection zones – and unfortunately, this is not a standard feature of personal emergency signal devices.

Furthermore, there is no normal GPS or mobile phone reception on the site, where every building has the effect of a Faraday cage.

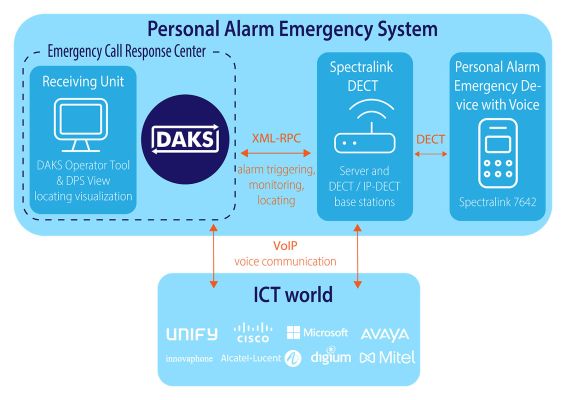

In the search for a cost-effective solution that also took into account the special requirements for the terminals, because in this case, personal safety had to be ensured in conjunction with DECT integration and Spectralink terminals, tetronik GmbH proved to be the most suitable partner.

The solution with DAKS®

From plans and antennas ...

After deciding on DAKS-PNA, tetronik's personal emergency signal system, the implementation required a lot of work and preparation. With great dedication, Mr. Kocher also took on tasks that are often outsourced and collected all existing site and fire protection plans in the summer of 2020.

The tetronik solution enabled him to contribute his own ideas and customize the visualization. For example, he photographed each of the 53 buildings and incorporated the photos into the visualization tool—because with a photo of the exterior, every employee knows intuitively what to do. He even took the trouble to measure the energy channel himself and create a 3D model of it. Today, he says with a smile and a shrug: “Other people have hobbies, right?” To ensure that reception on the site and in the buildings could function as comprehensively as possible despite the metal facades, over 200 DECT antennas were installed, most of them in additional explosion-proof housings.

Together with Mattias Sutter, who as security officer at Siegfried AG walks the entire site and every floor once a day and therefore knows it like the back of his hand, Mr. Kocher used a “hide and seek” game to identify those spots that were not yet adequately covered by reception. This enabled them to identify exactly where and how many antennas needed to be placed to enable comprehensive location tracking.

... via voice recordings and device tests ...

Mr. Kocher also personally took care of providing the voice texts that would be heard at the alarm receiving center. In order to achieve the highest possible acceptance among employees, the finished voice texts were generated with different female and male voices. The feedback from the test subjects was clearly in favor of a female voice—this was the voice that Swiss employees preferred to hear telling them what to do in an emergency.

With the end user always in mind, tests were also carried out to determine which of the many end device features in the Pharmapark were actually useful for employees. An entire afternoon was spent wearing “every conceivable type of glove” and protective clothing to determine what works well and what does not. For example, it was decided that a pull cord would be a good idea in addition to the alarm button due to the lack of fine motor skills.

... through to staff training and a finished alerting process

In 2021 the new system was finally ready for use. In a training session, the alarming procedure was clearly demonstrated to the employees. Everyone present was able to try out what happens when you stagger or fall over with the terminal device in your pocket or when you pull at the cord. It was also shown how the whole thing looks like on the side of the alarm receiving desk once an alarm goes off. Afterwards, the employees received the training materials as a printout, including a fail-safe 5-step guide for commissioning the terminal devices. In addition, one copy is available in each of the two alarm receiving locations. Since there are far more employees than available devices, a supervision protocol has also been stored there: if an employee takes a device from the charging cradle, this must be documented and signed so that it is clear who has which device in operation at any time. Employees are trained in such a way that they are able to train their own colleagues. This not only relieves the burden on supervisors, but is also expected to lead to greater acceptance from employees. Learning from colleagues also makes it easier to integrate the use of the system into the daily work routine.

Key components

DAKS-PNA, consisting of:

- DAKSpro 200 as Emergency Call Response Center

- DPS-View positioning and visualization software for DAKS

- DECT infrastructure IP-DECT server 6500 by Spectralink* with around 200 antennas

- DECT terminals: Spectralink model 7642 as Personal Emergency Signaling Device with Voice*

* the solution can also be implemented with end devices from other manufacturers

Success story as PDF

Discuss your individual application project with us

Add this solution

to your watch list

- Home

- Company

- Success Stories

- Employee safety at the pharma park

© tetronik GmbH. All rights reserved.